Question 1: The copper nozzle of the welding gun is always easy to be burned

Cause analysis:

During the welding process, heat diffuses to the copper nozzle and causes damage. The processing process should first analyze the heat source, lens astigmatism, red light polarization or external material heat conduction.

Solution:

Before processing, the following three aspects should be ensured:

① Red light is centered (polarization will cause light to hit the nozzle)

② Appropriate scanning width (generally within 5, usually set to 3)

③ Focus 0 focus (calibration tube can be 0)

1. First, send light to the ground from a long distance to see if the copper nozzle is hot. If it is not hot, it means that there is no problem with the lens and no astigmatism. If it is hot, the damaged lens needs to be replaced.

2. If the welding is hot under the above normal conditions, it means that the material is conducting heat during welding. In actual use, the outer corner copper nozzle is more easily damaged than the inner corner, and the copper nozzle can be used.

3. The welding technique also affects the heating. Try to weld the welding head and the material at 45°∠.

4. Highly reflective materials such as aluminum plates will also cause the copper nozzle to heat up, which is uncontrollable.

Question 2:The protective lens in the welding gun head is often burned out

Symptoms:

The protective mirror is damaged and burnt points appear in a short period of time. There are dot-shaped damaged points on the light-emitting surface of the protective mirror, showing black or black spots in white.

Cause analysis:

Due to the influence of process/technique/setting, the damage is caused by anti-slag, and in rare cases, the laser light is abnormal.

Solution

① Increase the air pressure appropriately. Under normal circumstances, the flow rate is not less than 15, the pressure is not less than 4, and it is recommended to use an oxygen pressure gauge of not less than 2 kg

② When welding, try to weld the welding gun and the plate at 45°, not vertical

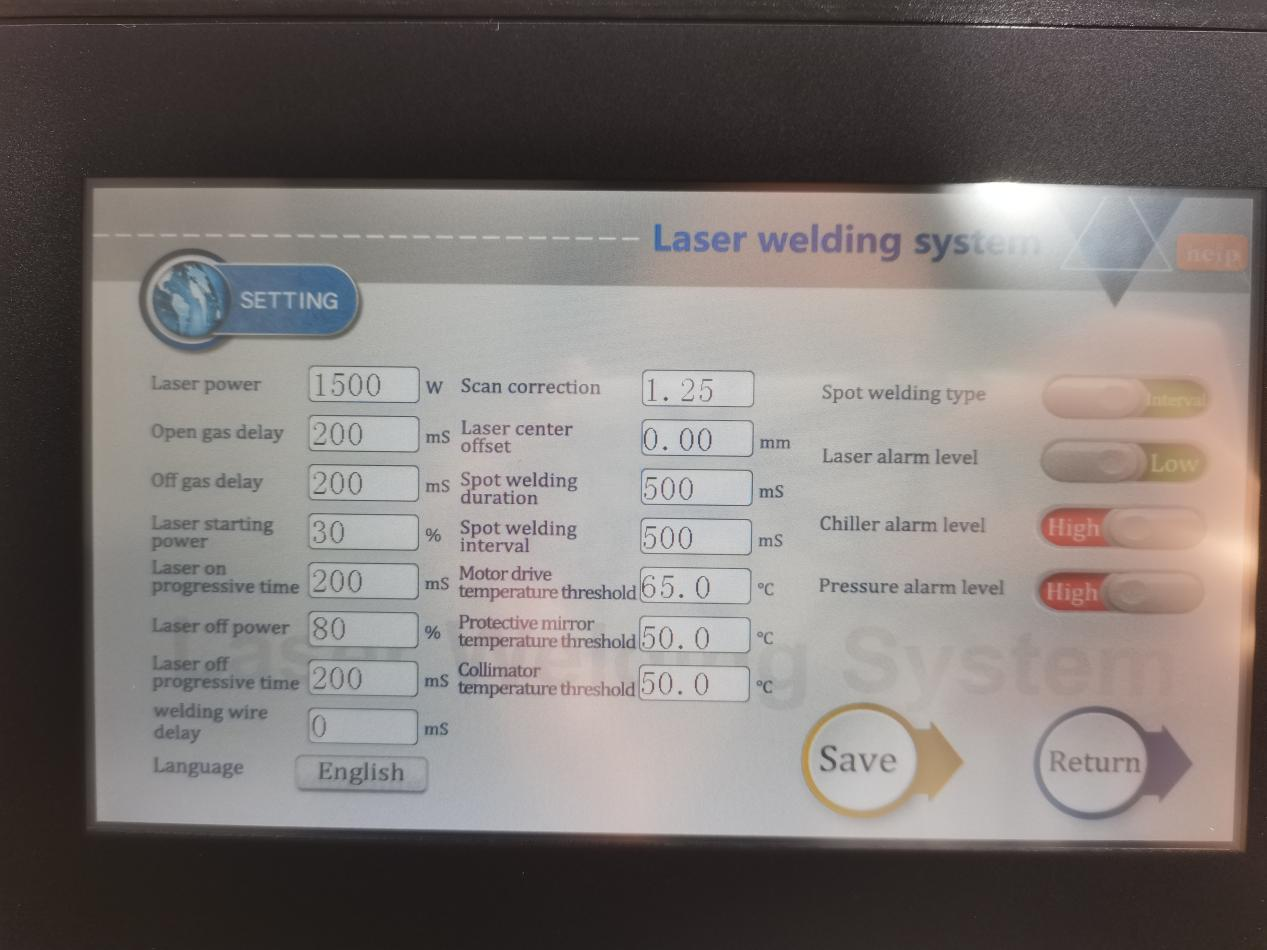

③ Set the parameters to give slow rise and fall as much as possible, such as 200-500ms on/off gas delay, 20% on/off light power, and 200-300ms on/off light progressive time. It cannot be set to 0 as shown in the figure

④ When welding aluminum and galvanized plates, this material is more likely to damage the lens than other materials, and the minimum power should be used for welding.

⑤The quality of the protective lens also determines its durability. It is recommended to use the original lens.

⑥At high power, the loss of the lens will increase compared to low power, which is an uncontrollable range.

⑦When the above cannot be handled, you can replace the F200 focusing lens + extended wide scale tube to reduce splashing (extra purchase required)